Table of Contents

- What Is Remote Asset Management?

- Why It Matters in Today’s Industrial World

- How Hydraquip Supports Remote Monitoring

- Key Capabilities You Can Leverage

- Real-World Use Cases

- The Technology Behind the Solution

- Benefits You Can Expect

- Why Engineers Choose Hydraquip

- Next Steps: Getting Started

-

What Is Remote Asset Management?

Remote Asset Management (RAM) is the ability to monitor, track, and manage industrial equipment and systems from a distance using connected technology. With RAM, engineers can gain visibility into the health, performance, and location of assets—without being onsite.

It’s like having eyes and ears on your equipment, no matter where it’s operating.

-

Why It Matters in Today’s Industrial World

In the age of digital transformation, efficiency, data-driven decisions, and proactive maintenance are non-negotiable. Unplanned downtime can cost thousands (or more) per hour. Remote Asset Management helps mitigate this by alerting teams before something goes wrong.

Whether you’re managing hydraulic systems, power units, or mobile equipment, staying ahead of failures is crucial—and RAM makes that possible.

3. How Hydraquip Supports Remote Monitoring

At Hydraquip, we understand your equipment is the heartbeat of your operation. That’s why we offer integrated telematics and control solutions that provide:

- Live monitoring of pressure, temperature, flow, and more

- Custom alerts via text or email

- Data logging for performance analysis

- Integration with existing equipment

Hydraquip’s tailored approach ensures that what you monitor actually matters to your operation—not just generic data points.

4. Key Capabilities You Can Leverage

Hydraquip offers powerful tools that make remote asset management straightforward and scalable:

- Customizable dashboards for monitoring multiple systems

- Predictive maintenance alerts based on real-time sensor data

- Geo-fencing and GPS tracking for mobile or rental equipment

- Historical data analytics for trends and decision-making

- Remote shutdown or parameter adjustment in critical situations

These features aren’t just bells and whistles—they’re essential for keeping systems running safely and efficiently.

Remote asset management isn’t just about monitoring—it also enables remote troubleshooting and support.

With the right setup, teams can:

- Remotely access systems to diagnose faults and guide on-site personnel

- Perform firmware updates or adjust parameters without rolling a truck

- Resolve issues faster while reducing service costs and downtime

5. Real-World Use Cases

Here’s how RAM is being used by engineers today:

- Rental fleets: Monitor location and usage of hydraulic power units to optimize deployment.

- Municipal fleets: Track pressure and temperature in utility equipment for compliance and safety.

- Construction equipment: Prevent overheating or contamination in mobile hydraulic systems.

- Oil & gas: Receive alerts on filtration issues or system failures before costly downtime occurs.

In each of these examples, the result is fewer surprises and more uptime.

6. The Technology Behind the Solution

Hydraquip’s solutions are powered by rugged IoT-enabled hardware paired with cloud-based software. Here’s what’s under the hood:

- PLC or HMI-based controllers

- Modbus, CAN bus, or proprietary protocols

- LTE/5G connectivity with fallback options

- Secure cloud access with user roles

- Sensor integrations for pressure, temp, flow, and vibration

The system is designed with reliability and cybersecurity in mind—critical for industrial applications.

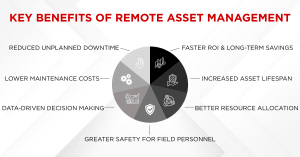

7. Benefits You Can Expect

When you work with Hydraquip to implement RAM, you’ll see tangible outcomes:

- Reduced unplanned downtime

- Customers have avoided costly failures—saving up to $10,000 per incident

- Early alerts and remote diagnostics help resolve issues before they escalate, contributing to a potential 20-50% reduction in downtime, as seen in industrial benchmarks

- Lower maintenance costs

- Customers have seen up to a 20% reduction in maintenance expenses within the first 6 months

- Optimized scheduling reduces unnecessary on-site visits, saving both time and money

- Faster ROI and long-term savings

- Many clients report payback periods as short as 9–12 months

- Increased asset lifespan

- Real-time monitoring and predictive maintenance extend the life of key systems by 20-40%, helping delay costly replacements and capital expenditures

- Better resource allocation

- Free up technician time by resolving issues remotely

- Deploy teams only when necessary, based on real data

- Data-driven decision-making

- Leverage historical trends to improve performance and plan future upgrades

- Greater safety for field personnel

- Fewer emergency callouts and less time spent around hazardous equipment

These aren’t just buzzwords—they’re measurable impacts reported by our customers.

8. Why Engineers Choose Hydraquip

Hydraquip has over 70 years of fluid power expertise, and we continue to evolve by integrating advanced controls and IoT technology. Engineers choose us because:

- We understand the engineering and mechanical side of your systems.

- We don’t sell cookie-cutter solutions—we customize to your specs.

- We support you long after install, with on-call expertise and maintenance services.

- Our partnerships with industry-leading OEMs and software providers ensure best-in-class tools.

We’re not just a vendor—we’re your long-term partner.

9. Next Steps: Getting Started

Interested in implementing Remote Asset Management? Here’s what to do next:

- Schedule a discovery call with our applications team.

- Discuss your current system and challenges.

- Get a tailored proposal with ROI estimates.

- Deploy the solution with training and support.

It’s that easy to get started—and the benefits are long-lasting.

Summary

Remote Asset Management is no longer a luxury—it’s a necessity. With increasing demands on uptime and safety, engineers need real-time insights to make informed decisions. Hydraquip delivers the technology and expertise to make that happen.

If you’re looking to modernize your operations, improve maintenance, and keep your assets running at peak performance—Hydraquip is here to help.

FAQs

- Does remote asset management work for legacy equipment?

Yes! Hydraquip can retrofit many legacy systems with modern sensors and communication tools. - Can I customize what data is monitored?

Absolutely. We work with you to identify KPIs that matter and configure monitoring accordingly. - Is the system secure?

Yes. Hydraquip uses encrypted communications and role-based access to ensure cybersecurity. - What happens if there’s no cellular signal?

Many systems offer satellite or local storage fallback to ensure data is never lost. - How quickly can I get started?

Depending on the complexity, most systems can be scoped and launched within a few weeks.